Description

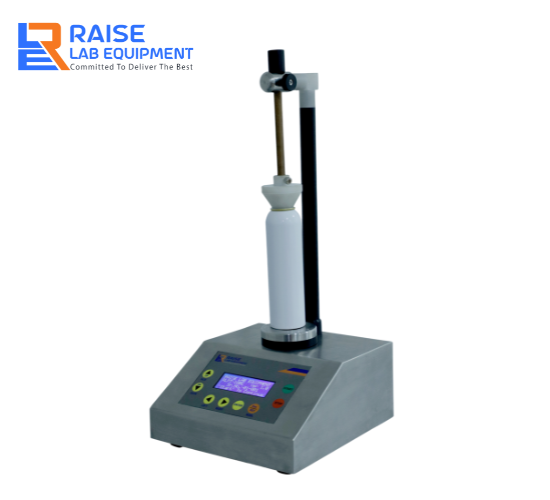

Lacquer Porosity Tester: The apparatus uses DC potential, a copper electrode and chemical solution to test the porosity that can be read through a digital display on the device. It is an easy and accurate method to know whether the lacquer coating is continuous or has any pores in it.

Raise Lab offers user-friendly and easy to operate Lacquer porosity testing apparatus that is as accurate as any other imported equipment.

Revolutionize Lacquer Porosity Testing with the RLP-1 Lacquer Porosity Tester

Introducing the RLP-1 Lacquer Porosity Tester, where simplicity meets precision in a single device. Designed to offer seamless usability and accurate results, this model sets a new standard in Lacquer Porosity testing, ensuring the integrity of aluminum tubes, cans, bottle caps, and foils.

The RLP-1 epitomises precision, innovation, and simplicity, standing as a testament to our commitment to excellence. Located at C-2, Industrial Park, Moula-Ali, Hyderabad, India, this instrument redefines Lacquer Porosity testing across industries, setting new standards of quality assurance. Welcome to a world where technological prowess meets user-centric design.