Are you concerned about the durability and quality of your tablet products? It’s crucial to understand that a Tablet Friability Tester can determine their longevity. This blog will guide you through everything you need to know, from understanding what friability testing is to choosing the best tester for your needs.

Keep reading to ensure your tablets withstand packaging, transportation, and ultimately impress end-users with their robust quality!

What is Tablet Friability Testing and Why is it Important?

Tablet friability testing is a crucial quality control measure in the pharmaceutical industry. It involves subjecting tablets to mechanical stress in order to assess their durability and resistance to breakage.

This testing ensures that tablets maintain their integrity during handling, packaging, and transportation. Furthermore, tablet friability testing is required by pharmacopoeia standards such as the British Pharmacopoeia (BP), United States Pharmacopeia (USP), and Indian Pharmacopoeia (IP).

Ensures tablet durability and quality

Tablet Friability Testers make tablets strong. These machines test if the tablets can hold up during travel. They need to be tough enough to not break, chip, or crumble when they are packed and shipped.

Tablets should also resist attrition. That means they don’t wear down when rubbed against a surface. A tablet that chips or breaks after being pressed is not good quality. So, these testers help keep the quality of tablets high and avoid damage during making them.

Required by pharmacopoeia standards (BP, USP, IP)

Tablet Friability testing is a must. It follows rules set by pharmacopoeia standards like BP, USP, IP. These standards make sure tablets are of good quality and safe for people to take.

The Roche friabilator often does the test as per USP guidelines. The test tells us how long a tablet can last without breaking apart. This is important because we need tablets to reach our stomachs in one piece!

Types of Tablet Friability Testing Machines

There are three types of tablet friability testing machines: single, double, and triple drum devices.

Single, double, and triple drum devices

Tablet friability testers come in three types: single, double, and triple drum devices. Single drum devices test one batch of tablets at a time. Double drum devices test two batches at once.

They work faster than single drums. Triple drum devices like the PTF 300 can do even more. It tests three batches of tablets all at once! All these types help check if tablets break or wear off too easily.

By using these tools, we make sure that every tablet you take is safe and works well.

Automatic testing machines

Automatic testing machines are key tools in tablet friability testing. They test many samples at once without help. Machines like the CS-1/2/3 Tablet Friability Tester do this job well.

There are also FRVi series and Friabimat testers available for use. PTFERA and PTFDR are other types of these machines that can work with one or more drums at a time. These machines make sure all tablets made meet high standards set by groups like the European pharmacopoeia and Indian pharmacopoeia.

Using an automatic tester from Raise Lab Equipment can save time and get good results every time.

Key Parts and Features of a Tablet Friability Tester

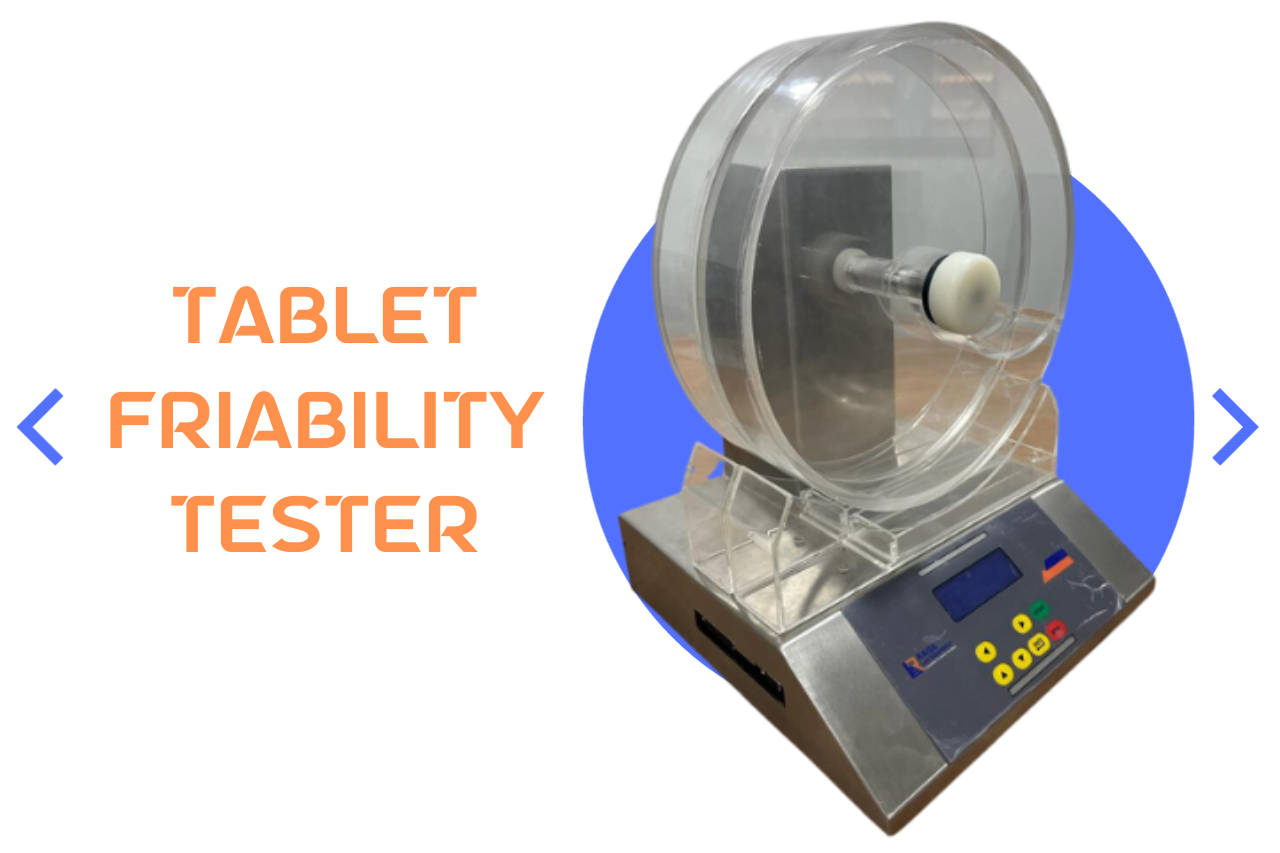

The tablet friability tester includes a calibration system, drums, silent DC gear motor, integrated report printing, click wheel navigation, and discharge collection tray.

Calibration system

A calibration system plays a key role in the tablet friability tester. It needs care and attention for precise test outputs. The age of the calibrator tablets, vessel shape, paddle or vessel misalignment, and system vibration can impact it.

These factors could change its sensitivity. To keep tests reliable, your machine should have proper alignment and shape of vessels and paddles. Plus, you need to limit any vibrations within the system.

Drums

Drums play a big role in a tablet friability tester. They are the round parts where tablets get placed for testing. These drums make sure the tablets can stand up to rubbing and falls.

The design and material of the drum matter a lot for good results. The Copley Friability Tester Model FRV 1000 uses one drum. Tablets ready for testing go into these drums.

Silent DC gear motor

A silent DC gear motor is part of the tablet friability tester. This key part spins the drums, letting them go around 25 times in a minute. The sound it makes is very low. So, it does not disturb you when you run tests.

Also, this motor keeps the drum speed steady for correct test results. Even with use all day, this tough part stays strong and works well.

Integrated report printing

The Tablet Friability Tester comes with an integrated report printing feature that is really useful for tablet manufacturing industries and quality control labs. This feature automatically calculates the weight loss after the tablet friability test and produces a detailed report.

The report includes important information such as the start time of the test, the operating mode used, and the set duration. It also documents the calibration results of the tester, ensuring standardized and reproducible documentation of its operation.

With this integrated report printing capability, it becomes easier to keep track of test results and maintain accurate records for regulatory compliance purposes.

Click wheel navigation

The tablet friability tester is equipped with a click wheel navigation system. This feature allows users to easily control and adjust the testing parameters with precision. Whether you are an experienced user or new to operating the tablet friability tester, the click wheel navigation makes it accessible for everyone.

It serves as a user-friendly interface, allowing you to navigate through the menu functions on the LCD display effortlessly. The click wheel navigation contributes to the functionality and ease of use of the tablet friability tester, ensuring a smooth testing process.

Discharge collection tray

The discharge collection tray is an important part of the tablet friability tester. It is magnetically fixed to the base of the machine and collects any fragments that may chip off or become powdered during the test.

This tray plays a crucial role in ensuring accurate and reliable results by preventing loose tablet fragments from contaminating the surrounding environment. It can be removed easily for cleaning and maintenance purposes, making it convenient to use.

So, if you’re in the tablet manufacturing industry or quality control labs, having a reliable discharge collection tray is essential for your tablet friability testing needs.

How to Choose the Right Tablet Friability Tester

To choose the right tablet friability tester, consider factors such as testing range, rotation speed options, and size and dimensions.

Testing range

The testing range is an important consideration when choosing a Tablet Friability Tester. It refers to the amount of tablets that can be tested at once. Different machines have different testing ranges, so you need to choose one that matches your production needs.

Some testers can handle a small number of tablets, while others are designed for larger batches. Consider the size of your operations and how many tablets you need to test in order to find the right tester for your needs.

Make sure it falls within the range required by pharmacopoeia standards, such as BP, USP, and IP.

Rotation speed options

The rotation speed options of a tablet friability tester are important to consider when choosing the right machine. The rotation speed refers to how fast the drums turn during testing.

It is crucial to control this speed accurately for reliable and consistent results. Tablet friability testers typically have a fixed rotation speed of 25 times per minute (RPM), which is ensured by a synchronous motor.

The accuracy of the rotation speed is ±1rpm, ensuring precise testing of tablets. The drum rotates at an average speed range from 15 to 100 RPM, maintaining optimal conditions for testing tablet durability and quality.

Size and dimension

The size and dimension of a tablet friability tester play a crucial role in choosing the right one for your needs. It determines how much space it will take up in your laboratory or production facility.

If you have limited space or are operating on a small-scale, a compact and portable tablet friability tester would be more suitable. You also need to consider the weight and ease of transportation based on its size and dimension.

Ultimately, the size and dimension should align with your intended application and workload, ensuring efficient use of space while meeting your testing requirements.

Conclusion

In conclusion, tablet friability testers play a vital role in ensuring the durability and quality of tablets. With their precise calibration system, drums, and silent DC gear motor, these machines provide accurate results for quality control labs and tablet manufacturing industries.

By choosing the right tablet friability tester based on testing range, rotation speed options, and size dimensions, manufacturers can ensure the structural integrity of their tablets as per industry standards like European Pharmacopoeia and United States Pharmacopeia.

Invest in a reliable tablet friability tester today to uphold the highest quality standards for your tablets.