Particle size matters immensely in the pharmaceutical realm. When it comes to ensuring consistency and quality control, few instruments are as pivotal as the sieve shaker—an essential tool for particle size analysis in granular materials.

With a wealth of experience in the application of such specialised laboratory equipment, I bring forward insights into leveraging these devices for optimal results. Proficiency in sieving techniques is instrumental not just for adhering to stringent industry standards but also for enhancing product efficacy.

Understanding particle behaviour through sieve analysis helps pinpoint sizing irregularities that might compromise a product’s performance—a critical exercise when minute variations can have substantial ramifications.

By tapping into advanced sieve shaker capabilities, we unlock precision that traditional methods cannot match. The subsequent exploration divulges how this ingenious apparatus operates and why it merits attention from professionals dedicated to excellence in particle separation.

Discover how technological evolution empowers impeccable grain size distribution assessments within your grasp—proceed to unveil methodologies transforming particulate scrutiny.

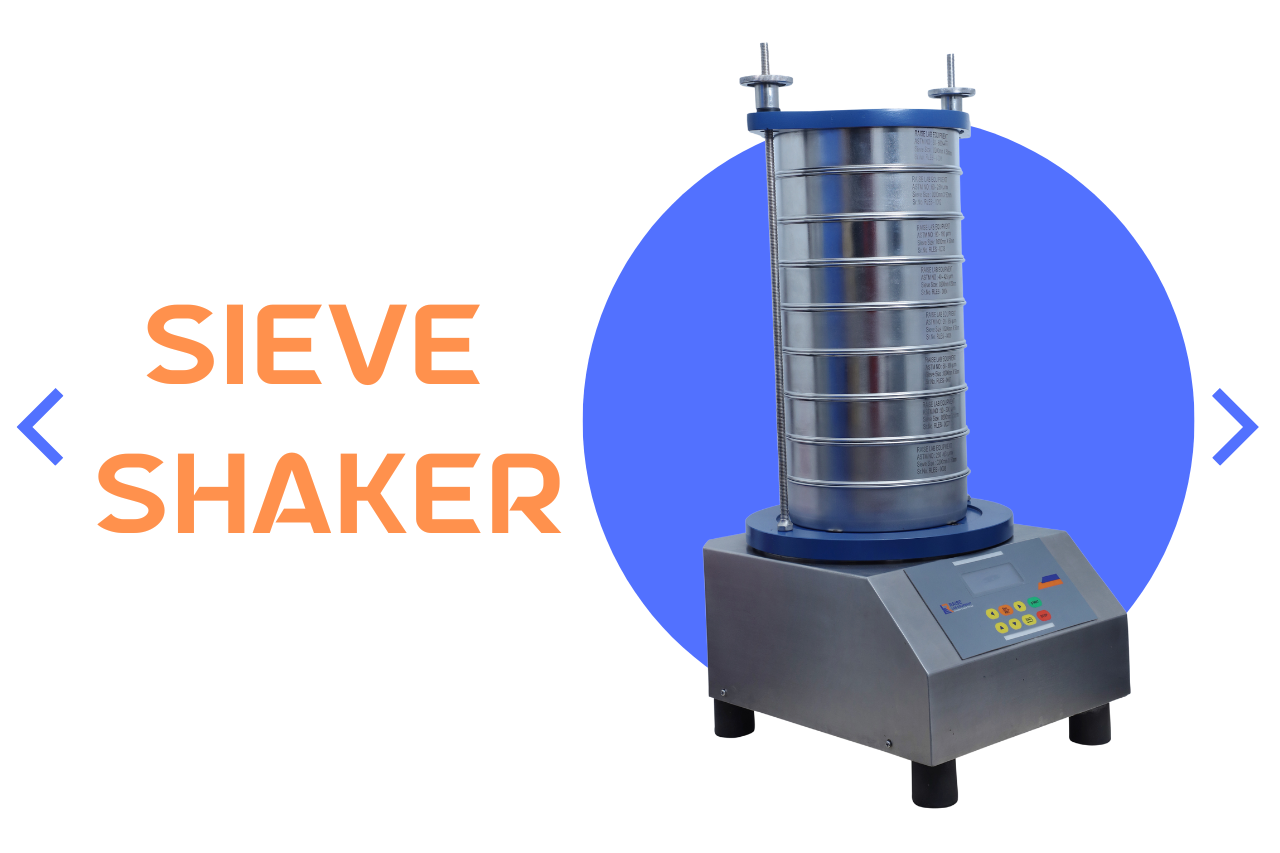

What is a Sieve Shaker?

A Sieve Shaker is a device used to shake stacks of sieves to efficiently separate particles. It works by moving in a way that forces particles through different levels, sorting them by size.

These machines are vital in the pharmaceutical industry because they help ensure powders and granules have the correct size. This matters a lot for how drugs work and their quality.

Different materials like stainless steel, brass, or copper can be used for the sieves themselves. The shakers have settings you can change to get just the motion you need for your specific test.

They come in several kinds: mechanical sieve shakers create motion with gears and motors; vibratory versions use high-speed energy to shake samples; sonic sieve shakers move air jets to shuffle particles around without touching them much.

Each type has its own benefits and is picked based on what’s being tested.

Advancements in Electromagnetic Sieve Shakers

From shaking particles through layers of mesh, we move to the latest technological leaps in sieve shakers. Electromagnetic technology has transformed particle analysis with precision sieving and improved vibration control.

Engineers have crafted machines like the RSS-1 by Raise Lab Equipment that provide advanced amplitude adjustment features. Users can finely tune vibrations to suit different materials and sieve sizes, ensuring accurate particle separation.

These innovative electromagnetic sieve shakers come equipped with heavy-duty bases for stability during operation. Their design allows for easy compliance with Pharmacopoeia standards, crucial for pharmaceutical industry work.

Versatility is a major benefit too – these devices support various sieve sizes, expanding their use across multiple applications. It’s all about reliable sieving results time after time, which is especially important when dealing with sensitive or critical materials typically found in pharmaceutical environments.

Applications of Sieve Shaker Machines

- In drug manufacturing, these machines help ensure that active ingredients are the correct size to work properly.

- Quality control teams use sieve shakers to check that powders meet strict size specifications.

- They assist in tablet production by sizing granules, leading to consistent tablet weights and dosages.

- Researchers rely on sieve shakers for particle size distribution studies, which can affect drug delivery methods.

- These machines support the development of suspensions and emulsions by separating out unwanted large particles.

- Sieve shakers aid in packaging processes where precise particle sizes are needed for efficient packing.

- The equipment helps maintain safety standards by removing contaminants that could affect drug purity.

- Pharmaceutical companies use them to prepare samples for regulatory compliance testing, ensuring all products are safe for use.

Choosing the Right Sieve Shaker

After exploring the various applications of sieve shaker machines, it’s now important to focus on selecting the best one for your needs. The right sieve shaker can make a big difference in your laboratory efficiency and accuracy. Here are key points to consider:

- Know your particle size range: Make sure the sieve shaker you choose can handle the specific particle sizes you need for pharmaceutical production. Check that it is compatible with sieves appropriate for those sizes.

- Consider performance requirements: Look for a shaker that meets Pharmacopoeia standards, ensuring compliance with industry regulations. Performance aspects such as adjustable vibration levels and amplitude range are also crucial.

- Think about usability: It should have user-friendly features like settable test times, quick locking knobs, and low noise operation. These features help to streamline your workflow.

- Assess construction materials: Seek out machines with robust construction such as a heavy base platform and optional cGMP (SS-316) material. They offer durability and contamination-free operations.

- Look at included certifications: Opt for models that come with individual calibration certificates for all sieves, guaranteeing precision in measurements.

- Evaluate cleaning processes: Easy-to-clean designs prevent cross-contamination between samples, which is vital in pharmaceutical settings.

- Analyse investment versus returns: While cost is an important factor, weigh it against the benefits offered by the sieve shaker. A lower upfront cost could mean higher long-term expenses if the machine isn’t durable or accurate enough.

Conclusion

Sieve shakers play a vital role in particle size analysis. They help scientists and engineers understand materials better. With the right machine, you can measure particles accurately.

Remember, choosing depends on your testing needs and budget. Sieve shakers ensure quality control across various industries.

FAQs

1. What is a sieve shaker used for in particle size analysis?

A sieve shaker is utilised to separate particles based on their size, ensuring accurate and consistent results for various applications.

2. How does a sieve shaker work?

By vigorously shaking a stack of sieves, the sieve shaker facilitates the passage of particles through the mesh, categorising them according to their sizes.

3. What types of materials can be analysed using a sieve shaker?

Sieve shakers are versatile tools capable of analysing a wide range of materials including aggregates, minerals, chemicals, pharmaceuticals, and other granular substances.

4. Can I use a manual or automatic sieve shaker for particle size analysis?

Both manual and automatic sieve shakers are suitable for particle size analysis depending on the volume of samples and the level of precision required.

5. Are there any specific precautions to consider when using a sieve shaker?

Ensure that all components are securely in place before operation to prevent accidents or inaccuracies during particle size analysis.