Revolutionizing Particle Analysis: The Science Behind Electromagnetic Sieve Shakers

Particle analysis is a fundamental aspect of quality control and research across various industries, including pharmaceuticals, food processing, and construction. One of the key instruments used for particle size analysis is the sieve shaker, and in recent years, electromagnetic sieve shakers have emerged as a revolutionary technology in this field. This blog delves into the principles behind electromagnetic sieve shakers, their operation, and their importance in different industries.

The Basics of Sieve Shakers

A sieve shaker is a device that uses mechanical vibrations to facilitate the separation of particles based on size. The process involves placing a sample of material on a stack of sieves with progressively smaller mesh sizes and shaking them. The particles are then sorted by size, with finer particles passing through the smaller meshes while larger particles remain on top of the sieves.

Traditional sieve shakers rely on mechanical movements such as tapping, shaking, or spinning to achieve this separation. While effective, these methods can have limitations in terms of precision, efficiency, and repeatability.

The Emergence of Electromagnetic Sieve Shakers

Electromagnetic sieve shakers represent a significant advancement over traditional mechanical shakers. They utilize electromagnetic forces to generate vibrations, providing a more precise and efficient method of particle size analysis.

How Electromagnetic Sieve Shakers Work

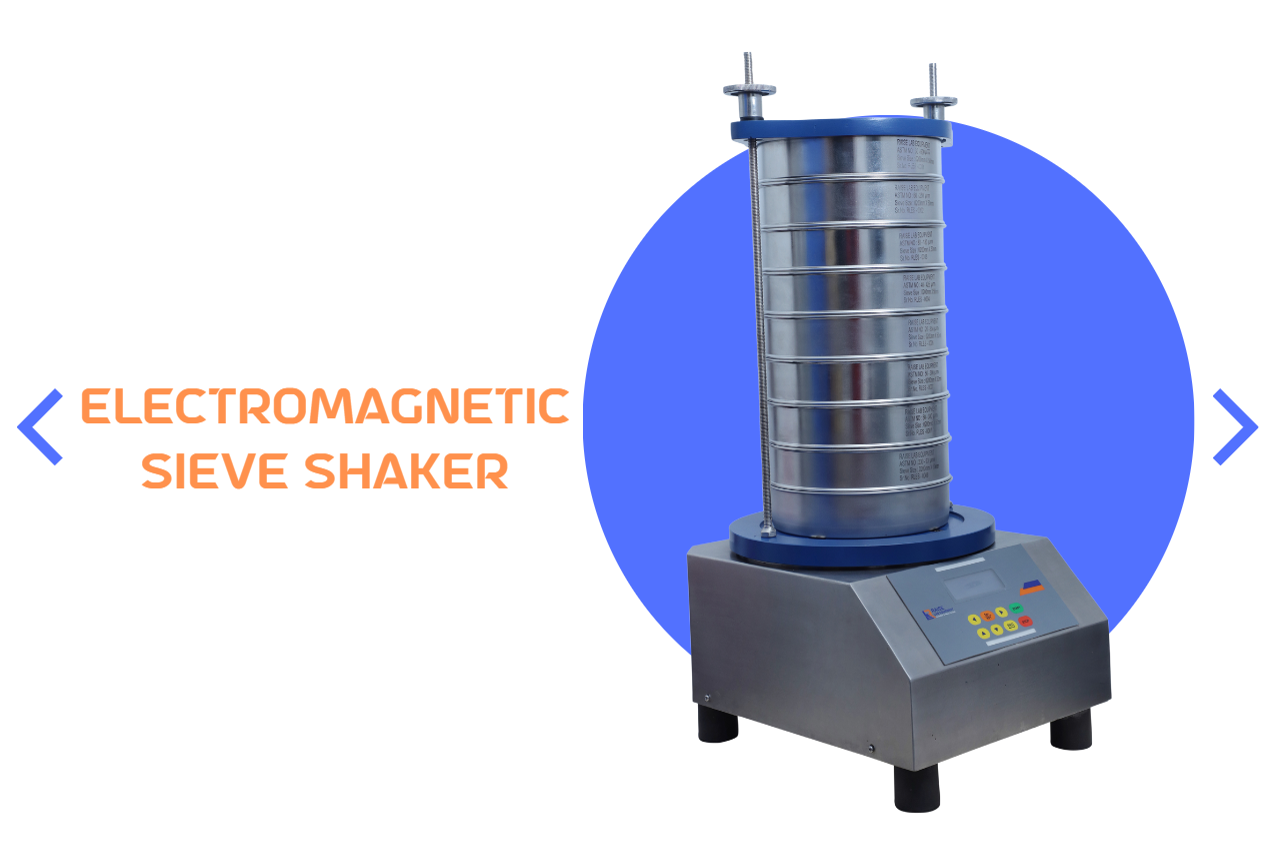

Electromagnetic sieve shakers operate on the principle of using electromagnetic waves to create vibrations. The key components of an electromagnetic sieve shaker include:

- Electromagnetic Drive: At the heart of the device is an electromagnetic drive unit that converts electrical energy into mechanical vibrations. This drive generates a controlled and consistent vibration pattern.

- Control Unit: This unit allows users to adjust the frequency and amplitude of the vibrations, providing precise control over the shaking process.

- Sieve Stack: Similar to traditional sieve shakers, electromagnetic sieve shakers use a stack of sieves with varying mesh sizes. The sample material is placed on the top sieve, and the vibrations facilitate the separation of particles.

The electromagnetic drive creates vibrations by oscillating at a high frequency, typically between 3,000 and 3,600 vibrations per minute. This rapid movement causes the particles to move and separate efficiently. The control unit enables operators to fine-tune the vibration parameters, ensuring optimal separation for different types of materials.

Advantages of Electromagnetic Sieve Shakers

Electromagnetic sieve shakers offer several advantages over traditional mechanical shakers:

- Precision and Consistency: The ability to precisely control the frequency and amplitude of vibrations results in highly consistent and repeatable particle size analysis. This is crucial in industries where precise measurements are essential for quality control.

- Efficiency: The high-frequency vibrations generated by electromagnetic drives enable faster and more efficient separation of particles. This reduces the time required for analysis and increases throughput.

- Versatility: Electromagnetic sieve shakers can handle a wide range of materials, from fine powders to coarse aggregates. This versatility makes them suitable for various industries and applications.

- Reduced Maintenance: With fewer moving parts than mechanical shakers, electromagnetic sieve shakers typically require less maintenance and have a longer lifespan.

- User-Friendly Operation: The advanced control systems of electromagnetic sieve shakers are often more intuitive and easier to use, reducing the learning curve for operators.

Features of the Rise Lab Analytical Sieve Shaker

- Pharmacopeia Compliance: Meets all necessary pharmacopeia standards.

- Robust Design: Features a unique heavy base platform designed for sustained vibration.

- Adjustable Vibration Levels: Offers adjustable amplitude ranging from 0.5 to 3.0 mm.

- Comprehensive Support: Equipped with a lid and receiver; allows for customizable test time and intervals.

- Low Noise Operation: Operates quietly with easy-to-use quick locking knobs for secure sieve fixation.

- Easy Maintenance: Designed for easy cleaning and contamination-free operation.

- Versatile Sieve Support: Accommodates 100×25 mm sieves (up to 16 sieves) and 200×50 mm sieves (up to 8 sieves).

- Model RSS-1: Available with optional cGMP (SS-316) material construction.

- Advanced Technology: Utilizes an electromagnetic drive with flexible non-metallic strips for amplitude adjustment.

- Maintenance-Free: Service-free equipment that runs on a 230V, 50Hz power source.

- Standards Compliance: Optional supply of ASTM and BSS standard sieves based on user specifications.

- Security Features: Includes password protection and SOP storage capabilities.

Applications in Various Industries

The versatility and precision of electromagnetic sieve shakers make them indispensable in numerous industries. Here are some examples of how different sectors benefit from this technology:

Pharmaceuticals

In the pharmaceutical industry, particle size analysis is critical for ensuring the quality and efficacy of drugs. The size of particles can influence the dissolution rate, bioavailability, and stability of medications. Electromagnetic sieve shakers provide the precision needed to meet stringent regulatory standards and ensure consistent drug formulations.

Food Processing

Food processing relies on particle size analysis to maintain product quality and consistency. For example, in the production of flour, sugar, and spices, consistent particle size is crucial for texture, taste, and shelf life. Electromagnetic sieve shakers enable food manufacturers to achieve uniform particle sizes, enhancing product quality and consumer satisfaction.

Construction

In the construction industry, particle size analysis is essential for materials such as sand, gravel, and cement. The quality and performance of concrete and other building materials depend on the correct particle size distribution. Electromagnetic sieve shakers help ensure that construction materials meet industry standards, leading to stronger and more durable structures.

Environmental Analysis

Environmental agencies use particle size analysis to monitor soil and sediment samples. Understanding the particle size distribution of these samples can provide insights into soil health, erosion patterns, and pollution levels. Electromagnetic sieve shakers offer the accuracy needed for reliable environmental assessments.

Mining and Minerals

The mining industry relies on particle size analysis to optimize the extraction and processing of minerals. The efficiency of separation processes such as flotation and gravity separation depends on the precise control of particle size. Electromagnetic sieve shakers contribute to improved recovery rates and product quality in mining operations.

Conclusion

Electromagnetic sieve shakers represent a significant advancement in particle size analysis technology. Their ability to provide precise, consistent, and efficient separation of particles makes them invaluable across a range of industries. From pharmaceuticals to construction, these advanced devices ensure that materials meet quality standards and perform as expected.